Industrial Adhesive Manufacturer and Supplier

At ACROM, we design more than just industrial glues. We develop complete assembly solutions, tested and validated to meet the specific technical requirements of every client.

As a supplier of industrial adhesives for over 20 years, our ambition is clear: to combine commercial responsiveness, bonding engineering, and product innovation.

Acrom: Your Expert Partner in Industrial Bonding

Every industrial project is unique. That is why we have chosen not to be mere resellers. Our bonding test laboratory in La Séguinière (Western France) is at the heart of our approach.

This facility allows us to evaluate the performance of every adhesive under real-world conditions: specific material types, temperature variations, mechanical stress, and simulations of your production constraints. Consequently, we offer bespoke adhesives adapted to highly specific use cases, ensuring our clients receive unique, high-performance bonding products.

✔️ Bespoke Consultancy: Our technicians guide you toward the most suitable adhesive for your application (mechanical strength, environmental conditions, curing time, substrate compatibility, etc.).

✔️ Renowned Distribution Partners: We distribute adhesive product references recognised for their performance and reliability, alongside a wide range of dispensing equipment adapted to these products.

✔️ Responsive Logistics: Our products are available from stock or can be delivered rapidly throughout France and Europe.

✔️ Continuous Technical Support: We accompany you through the testing, qualification, and process optimization phases.

Building on our laboratory work, our team travels to your facilities across France and Europe to test, adjust, and validate our adhesives directly within your production environment. This dual level of expertise guarantees our clients reliable, durable bonding solutions perfectly integrated into their processes.

A Complete Range of Industrial Adhesives for Every Need

We provide your teams with a wide selection of industrial adhesives:

- Solvent-based Adhesives (Neoprene, Polyurethanes, Synthetic Rubbers): For manual or spray application covering full surfaces; compatible with leather, wood, or technical fabrics.

- Two-Component Adhesives (Methacrylates, Acrylics, Polyurethanes, Cyanoacrylates): Specific solutions for metal, plastic, glass, and composites.

- Industrial Sealants and Silicones: Ideal for applications exposed to significant variations in temperature or humidity.

- Hot-Melt Adhesives: For optimised setting times and use in automated systems.

Every product is tested, documented, and compliant with current industrial standards.

Solutions for All Industrial Sectors

Our expertise covers a wide variety of fields:

- Transport: We supply adhesives tailored to the marine, railway, and automotive sectors. These applications demand products resistant to vibrations, thermal shock, and mechanical fatigue. Our solutions guarantee durable adhesion on metal, composites, or thermoplastics.

- General Industry: The vast and demanding industrial world imposes specific constraints. We respond by offering solutions adapted to the environments of sectors such as signage, plastics processing, metallurgy, and composite materials.

- Construction & Building: For manufacturers of technical equipment, joinery, or insulation solutions, we offer adhesives for structural bonding, sealing, or heavy material assembly (wood, concrete, steel, PVC, etc.). Our glues are adapted to both on-site constraints and workshop production.

- Leather / Textile: In the fields of technical leather, coated textiles, or flexible materials, we offer contact adhesives (solvent-based or solvent-free) compatible with industrial production speeds. Ideal for flexible assembly, finishing, or manufacturing specific components.

Every sector has its constraints. Our role is to help you anticipate them by proposing industrial adhesives perfectly suited to your business requirements.

Best Practices: Using and Storing Your Industrial Adhesives

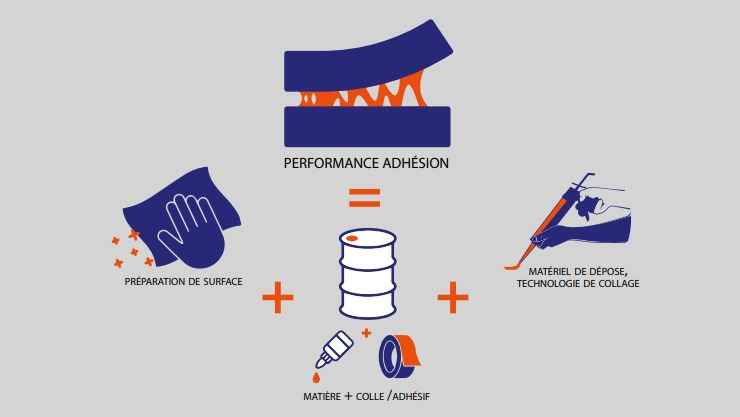

The efficiency of an adhesive depends on its correct usage. Acrom provides all necessary Technical Data Sheets (TDS) and safety instructions, along with practical recommendations on:

- The preparation of surfaces to be bonded;

- The dosage and mixing of adhesive components;

- The storage conditions (temperature, humidity, shelf life) of our products.

Our team can train you on the optimal use of each product and its storage, or suggest alternative practices that could improve your yield.

FAQ

1. Which adhesive should I choose for a metal/plastic assembly?

It depends entirely on the type of plastic and the conditions of use. Our experts can guide you toward a methacrylate or polyurethane adhesive specifically designed for dissimilar materials.

2. Is bonding possible at low temperatures?

Yes, certain formulations allow for bonding in cold or humid environments. Contact us to arrange a feasibility test.

3. Which glue is best for high mechanical vibrations?

MS Polymer sealants or technical silicones are often recommended for their flexibility, but specific trials are indispensable to ensure reliability.

4. Do you offer food-safe certified adhesives?

Yes, we supply adhesives compliant with European regulations for indirect food contact.

5. Does Acrom develop its own adhesives?

Yes, we develop a portion of our range in our laboratory in La Séguinière, France. However, we also co-create bespoke products with specialised manufacturing partners.

6. Can we receive samples for testing?

Yes, we encourage testing and prioritize our presence during supervised trials to ensure success.

7. Can Acrom train our teams on adhesive application?

Yes, we offer on-site or remote training to optimise the application of our glues and silicones.

8. Do you have safer options for operators?

Yes, our range includes several solvent-free references and products free from CMR (Carcinogenic, Mutagenic, Reprotoxic) substances, suitable for sensitive environments.

9. What is the average shelf life of industrial adhesives?

It varies between 6 and 24 months depending on the product. Respecting storage conditions is essential to guarantee bonding performance.

10. Can Acrom integrate its solutions into an automated line?

Yes, we collaborate with integrators and offer adhesives compatible with dispensing equipment, whether automated or manual.

Comprehensive Support for Your Adhesive Procurement

As an industrial adhesive manufacturer and supplier, we do not just sell a product. We build a relationship of trust based on technical expertise, responsiveness, and transparency. Our products must meet all your expectations: regulatory compliance, efficiency, pricing, and delivery.

???? Need a quote, a product test, or advice? Contact our teams. Together, let's find the industrial adhesive that perfectly matches your production challenges.

A Hands-On Company: Locally Rooted, Future-Focused

We are established in La Séguinière (Western France), strategically located between Angers, Nantes, and La Roche-sur-Yon. We can ship our adhesives rapidly across Europe, whether for a standard restocking or a production emergency. Everything is managed on-site, with real tracking and available support teams.

At ACROM, we also think about the future. For several years, we have been committed to a concrete CSR (Corporate Social Responsibility) strategy. This focuses on local employment, waste reduction, leaner resource usage, and improving working conditions.

This CSR approach was formalised in 2023 and evaluated by EcoVadis, proving that our commitment goes beyond words.

EcoVadis is a platform for evaluating corporate social responsibility (CSR), allowing organisations to measure and improve their performance. The scoring system is based on a personalised questionnaire, taking into account dimensions such as the environment, human rights, and business ethics. Globally recognised, the platform connects a network of over 85,000 evaluated companies.